Quality process

Our products are manufactured under a strict quality control system that ensures they meet the highest standards.

The QC Department conducts detailed checks on all aspects of the product, including the yarn, selvages, weight, width, shrinkage, skewness, and color fastness. All results are recorded and tracked.

Once the inspection is complete, the fabric is graded according to international standards using the ASTM 10-point scoring system.

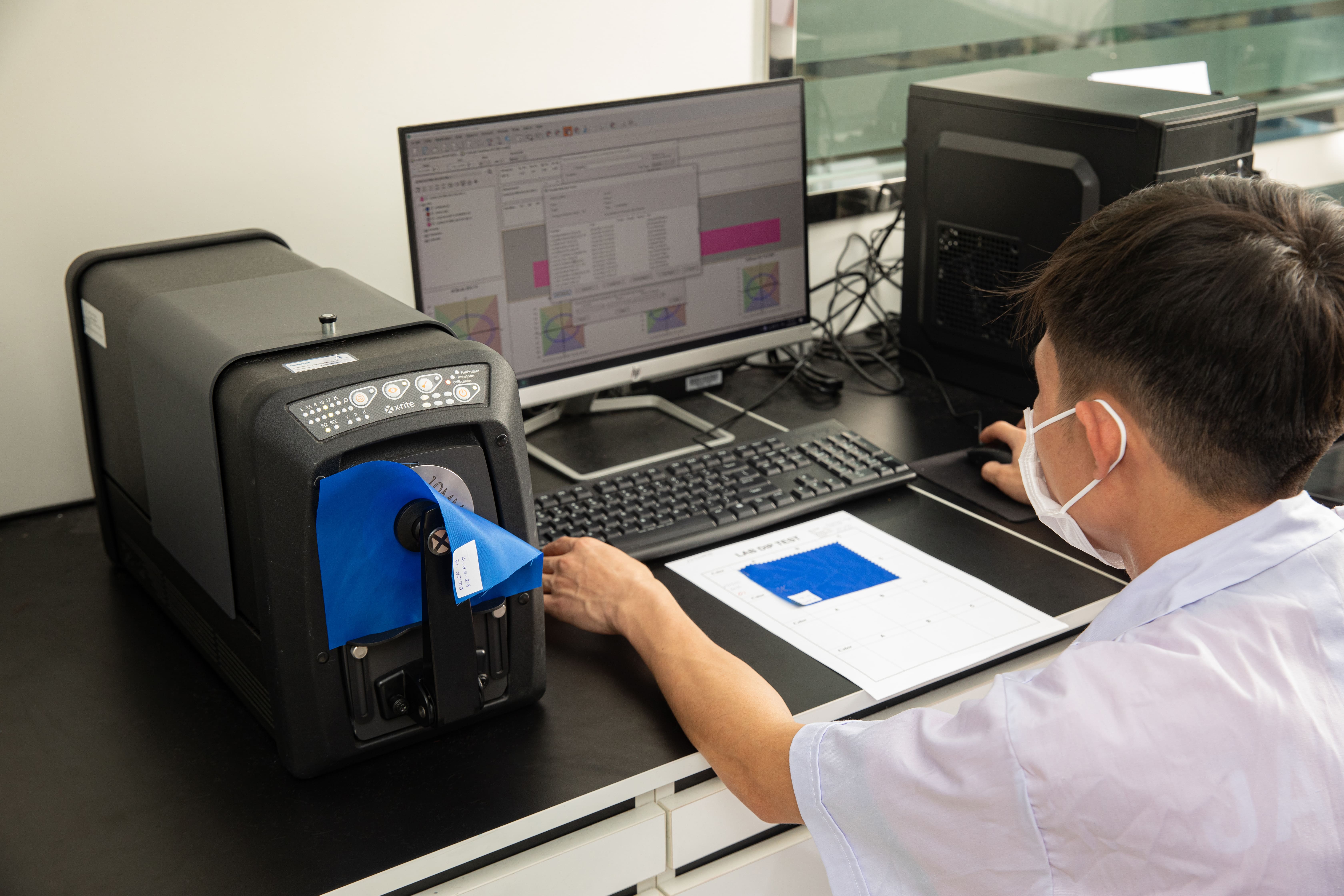

Laboratory - creative thinking solutions

Our laboratory is a microcosm of our real factory, where we use the most modern and advanced equipment to develop custom-made products that are both creative and environmentally friendly.

We meticulously test finished synthentic woven fabrics, lining fabrics and fusible interlinings in accordance with the most relevant standards and customer-specific requirements. Interlinings are tested to ensure the quality of their main performance, such as bond strength and shrinkage before and after washing.

JayJay also tests interlinings on customer-specific fabrics to recommend correct fusing machine setting conditions such as a fuse line temperature, dwell time, and roller pressure.

Certificates and Patents

We are proud to have acquired these internationally recognized certificates and patents, which are a testament to our safe, consistent, and sustainable production system.